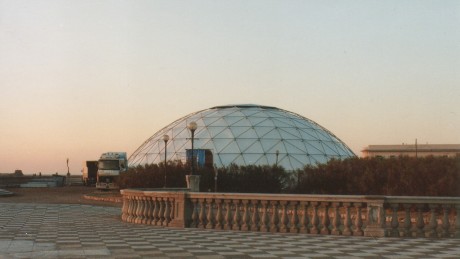

Sports facilities covers with geodetic structures

Sports facilities covers with geodetic structures

The optimal sports coverings are realized with the "Geodetic Tensint" structures, they are realized with the technology that is based on precise geometrical calculations.

The geodesic structures can solve problems of covering large areas without the aid of intermediate pillars, obtaining an "open space" space that can be used and modified in use.

This type of structure has different varieties of types including:

- Sports facility cover with external or hanging membrane.

- Rigid cover with insulated panels, polycarbonate or glass.

Possible types

- With regular plant

- Square-shaped

- With a rectangular plan

- With a circular plan

- With an oval plant

- Cover with external cloth

- Cover with hanging cloth

Documentation

Each "Geodesic Space Reticular Structure" is designed in compliance with the new NTC2018 Regulations and is accompanied by all the documentation necessary for the deposit to the Civil Engineers and for any Seismic approval including the "Ten-Year Guarantee" of the Certification structure of materials and POS (Operational Safety Plan).

Construction

The geodesic structures are built by developing a triangular mesh, square or rectangular lattice scheme stiffened by the diagonals outside the plane that flow into internal nodes that link the structure spatially.

This lattice is realized with the union of the rods at the nodes.

The rods are equipped with special threaded couplings that allow a bolt to join them to the various knots that make up the structural scheme.

The rods are made of tubular profiles of circular, square or rectangular section and dimensioned in consideration of the structural calculation that determines their lengths and their geometrical characteristics, such as dimensions, diameter and thickness.

The joints or knots are made of quality steel forged shells are made holes for the passage of the screw, with the angles required to get the shape you want.

The nodes used for the traditional geodesic structures have the characteristic of having a spherical or semi-spherical shape of dimensions such that they do not protrude from the external thread of the rods, in order not to create protruding points that can prevent the correct and continuous covering of the covering.

Coverage

The covering of a geodesic structure can be realized in different materials: PVC membranes, rigid panels or glass.

The most widespread and economic coverage is that obtained with the use of PVC sheets, which can be made outside the structure or inside it.

In the latter case, the cover must be fixed, tensioned and stabilized by means of cables or chains which must connect the double anti-parchment disks, blocking the covering membrane, and the nodes which are fixed attachment points of the geodesic structure. .

In the event that the cover is positioned outside the structure, it can be fixed and tensioned in two ways: by inserting suitable tie rods (Ratchets), which connect the tubular profiles inserted into the bags welded on the sheet and the perimeter anchors fixed frames of the structure; or through the welding inside the cloth of an appropriate number of horizontal eyelet bands, which allow the elastic rope, passing inside the eyelets and around the horizontal rods, to lengthen and withdraw, thus dissipating energy, so as to keep the membrane tensioned of coverage subjected to climatic actions due to snow and wind.

The sheets used to make the covering membranes are impermeable, with interposed a high-tenacity polyester fabric of type 1 classified B-s1-d0, covered on both sides with polyvinyl chloride (PVC) and are made of polyester fabric , coated on both sides, with fireproof treated PVC of type 1 class B-s1, d0.

The covering membranes can be realized with the packaging of a simple cloth or to be more efficient from the energetic point of view with the coupling of two sheets spaced from each other thanks to the air pushed inside the created air space.

The covering can also be made with rigid and insulated panels, obtained by coupling two sheets that contain the insulating material, which can be polyurethane, polystyrene, rock wool so as to choose the most suitable coupling to the specific needs.

These sandwich panels can be made of the desired dimensions, in order to obtain the polygonal shape with their tile overlap. This effect is obtained by bending about 250 mm. of the end part of the upper sheet of the curvature angle of the geodesic structure required to follow the shape of the structure, so that the inclined fin overlaps perfectly with the sheet of the lower panel, so as to obtain a covering which thanks to the overlap with the lower panel guarantees water and weather resistance.

Protection

- Electro-IT galvanizing

- Hot galvanizing

- Painting with epoxy powders

- Painting with polyurethane powders

Assistance

- Assistance and maintenance service

- Setting up existing structures and related systems

- Cover membrane replacements

- Structural reinforcement for new rigid covering with panels

Accessories

The cover consists of a first main outer membrane, a second translucent and lighter inner membrane, welded to the first, and a third inner membrane welded to the other two.